BRF-series Centrifugal Pump

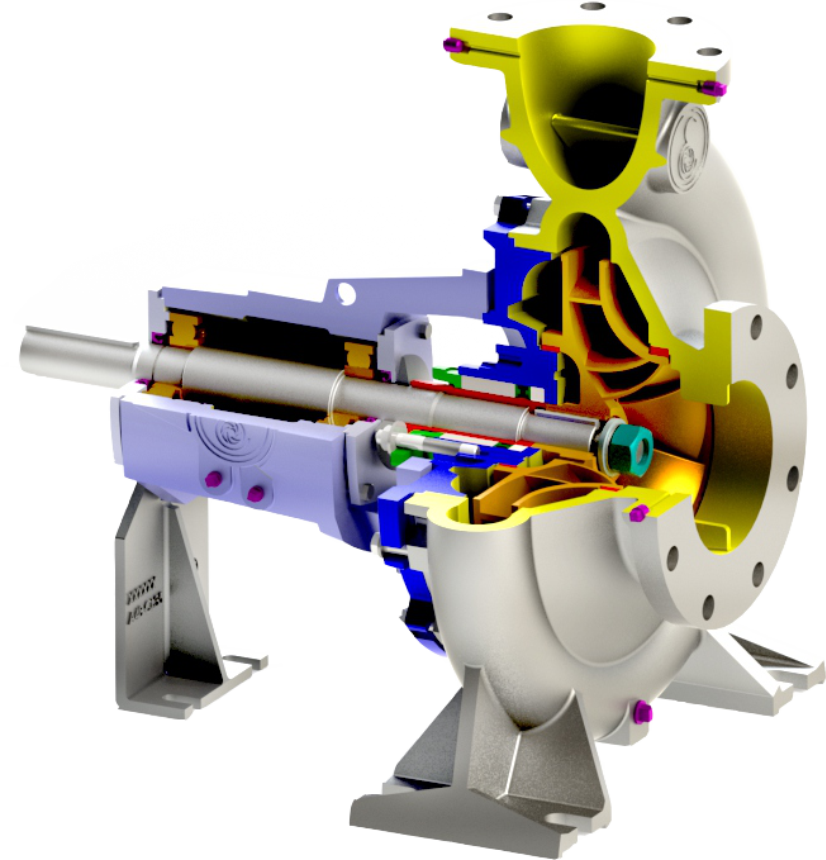

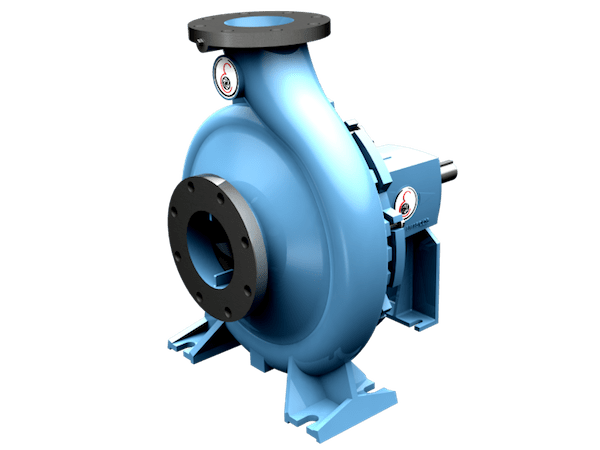

BRF-series Single-cell, Horizontal Centrifugal Pump with Closed Impeller

For over half a century, Equipe has been a synonym for innovation and competence in centrifugal pumps projects for the most diverse applications in the general industry segment.

As bombas centrífugas da série BRF são fabricadas focadas nos mais altos padrões de qualidade, geridos por melhorias contínuas dos padrões de qualidade, normalização e padronização de produtos e serviços em conformidade ao sistema de Gestão da Qualidade ABNT ISO-9001.

The safety and reliability of our products come from the conformity of these rigorous quality requisites.

They offer sturdiness, wear resistance, meaning savings in maintenance, fully covering the clients’ needs in terms of durability and efficiency.

The use of standardized components algo ensures high availability of OEM parts, normally available in stock.

Contact

comercial@equipe-bombas.com.br

Areas of usage:

- • Steel mills.

- • Paper and Cellulose industries.

- • Chemical industries.

- • Food industries.

- • Power supply.

- • City water supply and wastewater; treatment of raw sewage and/or wastewater in drainages in general.

- Pumping long fibers, muds, and sludge; fibrous pulp, fluid pastes and industrial effluents;

- Water/sand mixtures, slag and alike in mining industries;

- Wood chips with shavings;

- • Clean or slightly contaminated liquids, viscous liquids, etc.

Constructive Characteristics

Horizontal construction, single cell with closed impeller, horizontal simple suction, and horizontal discharge. Back pull-out design with bearing support, axis, rotor, and lid being detached from behind, avoiding disconnection of the system’s suction/discharge piping.

Dimensionally built according to DIN 24256 / ISO 2858, and mechanically built according to ASME/ANSI B-73.1.

The axis works with oil-bath lubricated ball bearings and the sealing can be done by conventional gaskets and/or mechanical seals.

According to the work conditions, cooling and/or internal/external sealing can be provided.

Flanges built according to ANSI.

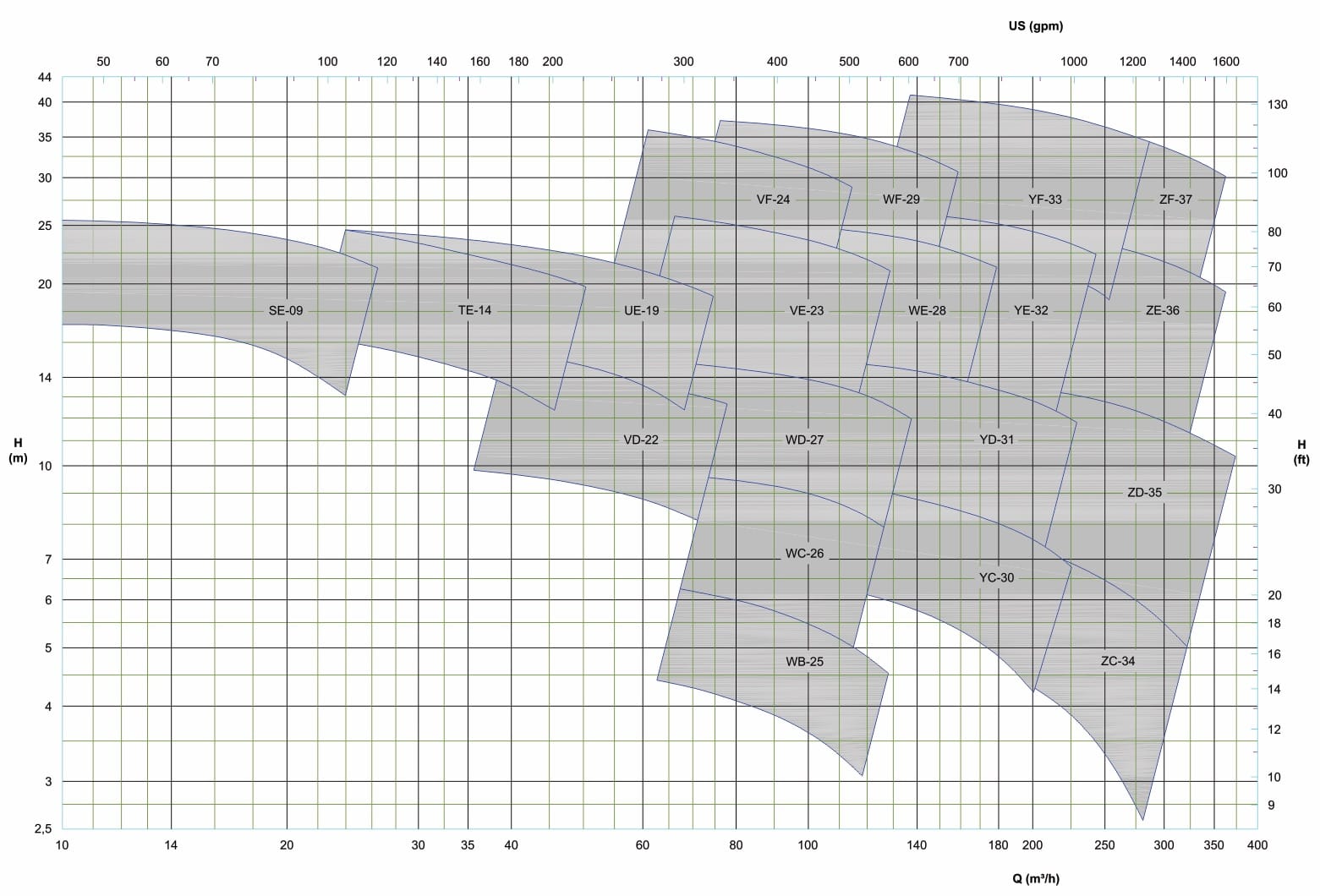

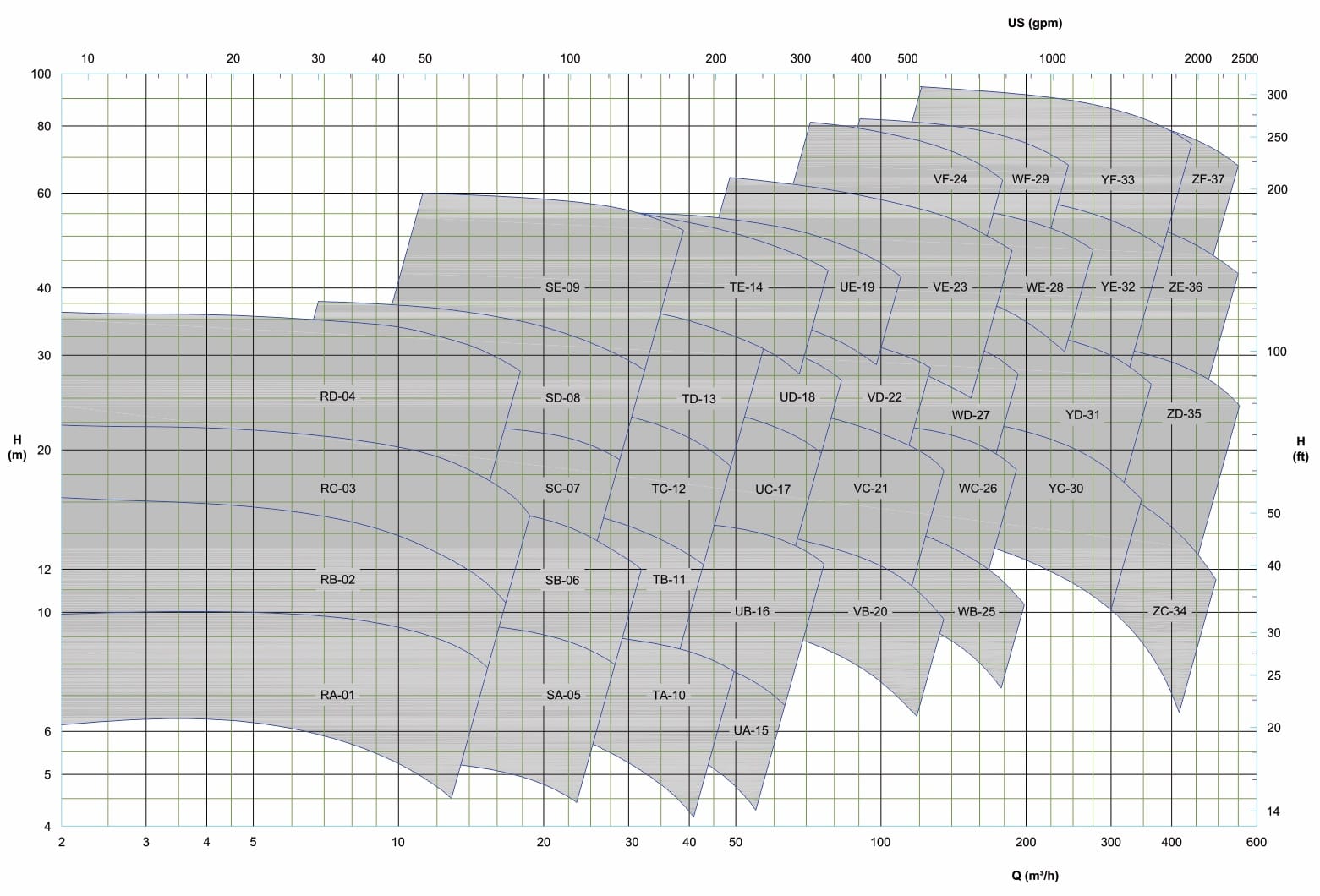

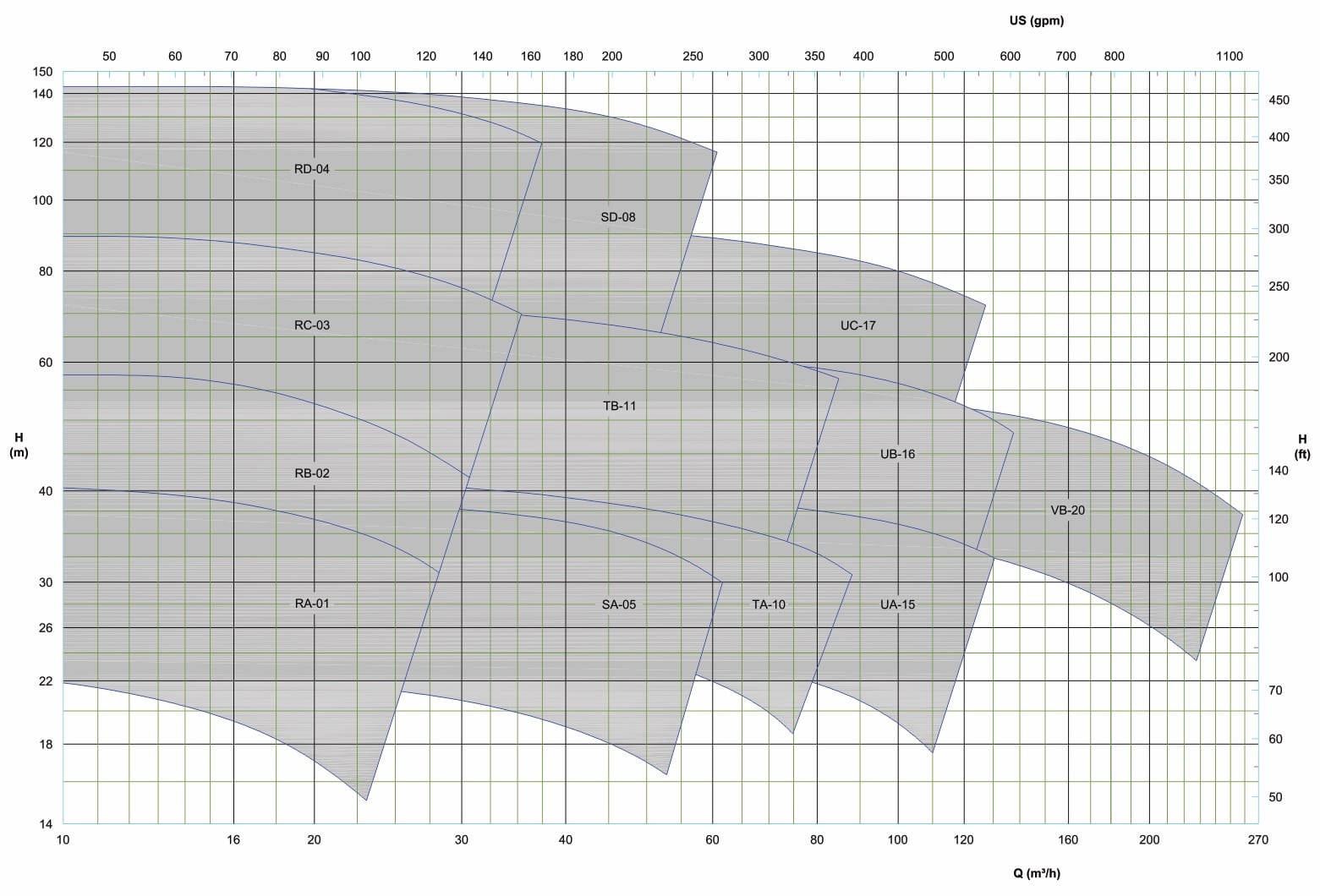

Hydraulic Characteristics

Flow: Up to 600 cu m/h

Head: Up to 140m

Temperature: Up to 150°C

Revolutions: up to 3500 rpm

Casing

For rougher transportation demands. Built in a single part, it houses the suction and discharge flanges in a Back Pull-out system.

Provided with a removable rear support for assembling it to the metal base.

Impeller

Closed, balance mounted. Statically and dynamically balanced to the axis.

Low NPSHr with high hydraulic frequency.

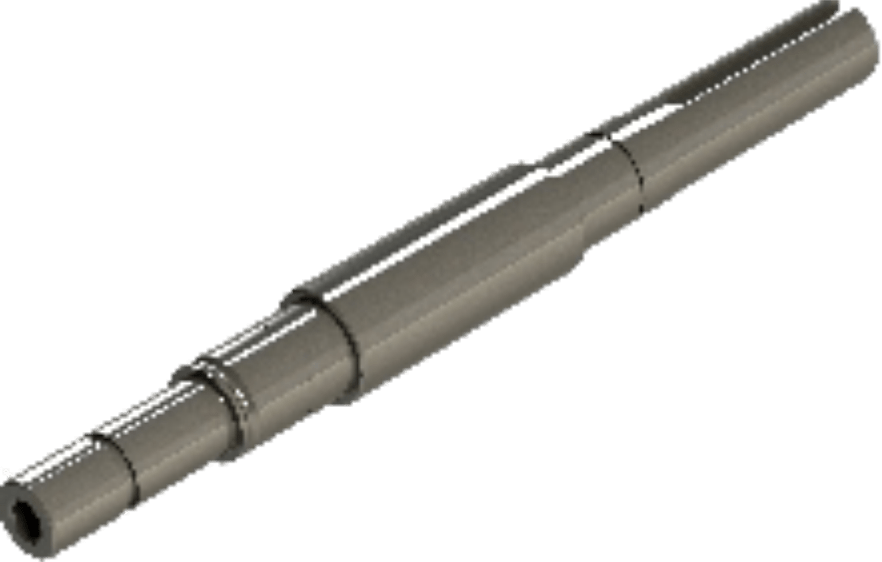

Shaft and Bearings

Compact ball bearings, oil-bath lubricated, with dimensions according to ISO 281 (ANSI/ABMA standard 9).

Axis for continuous services, projected for maximum load and minimum deflection.

Closed Impeller Horizontal Centrifuge

Construction

- Modular, with superior project characteristics; Reliability with maximum efficiency

- Reduced operational costs;

- High standardization level and replacement parts cost

Back Pull Out Design

Allows easy access to the rotating element and speed in maintenance, reducing costs and unprogrammed stoppages.

Construction Materials

Broad range and combination of materials available in connection to the pumped liquid.

Allows transportation of liquids with high suspended solids up to 150mm.

Replaceable wear plates with outlines designed according to the impeller project.

Superior project characteristics; impeller with double curvature; low required NPSH. Low energy consumption.

Conventional sealing projected according to ISO dimensional standards, with gaskets or mechanical seals single, double, sealing plans according to API-610 6th edition.

Axis projected for minimum deflections ≤ 0.05mm. Specific materials for each usage. Roughness, durability, and operational safety.

Compact and rough bearings, dimensioned with broad load capacity and long-lasting life. Oil-lubricated for temperatures of up to 120°C.

Projected casing, passage channel with broad transversal section, flow free of blockages.

Provided with replaceable wear bushing for protecting the axis against corrosion and wear.