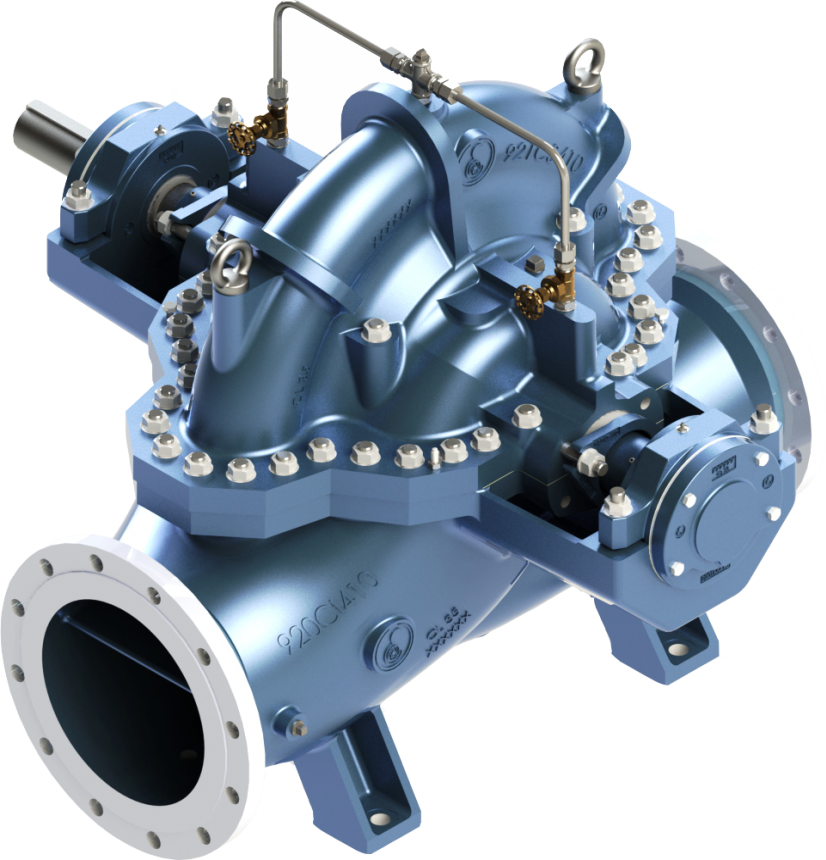

Double Suction Centrifugal Pump: RDS

Optimized design with a high degree of standardization, superior hydraulic efficiency, and low energy consumption make this design the perfect choice in general liquid transport.

All components are manufactured in compliance with quality standards, with ISO 9001 certification. They stand out in applications in Fire Fighting systems, complying with the NFPA-20 Standard.

They also find a wide field of application in pumping clean or turbid liquids and can be used in public or industrial supply stations, cooling water, cogeneration plants, paper and cellulose industries, collection, irrigation or drainage systems, cooling systems, chemical and petrochemical industries, steel mills, etc.

Contact

comercial@equipe-bombas.com.br

Areas of usage:

- • Steel mills;

- • Firefighting;

- • Irrigation;

- • Paper and Cellulose industries;

- • Chemical industries;

- • Food industries;

- • Power supply;

- • City water supply and wastewater; treatment of raw sewage and/or wastewater in drainages in general;

- Pumping long fibers, muds, and sludge; fibrous pulp, fluid pastes and industrial effluents;

- Water/sand mixtures, slag and alike in mining industries;

- Wood chips with shavings;

- Clean or slightly contaminated liquids, viscous liquids, etc.

Constructive Characteristics

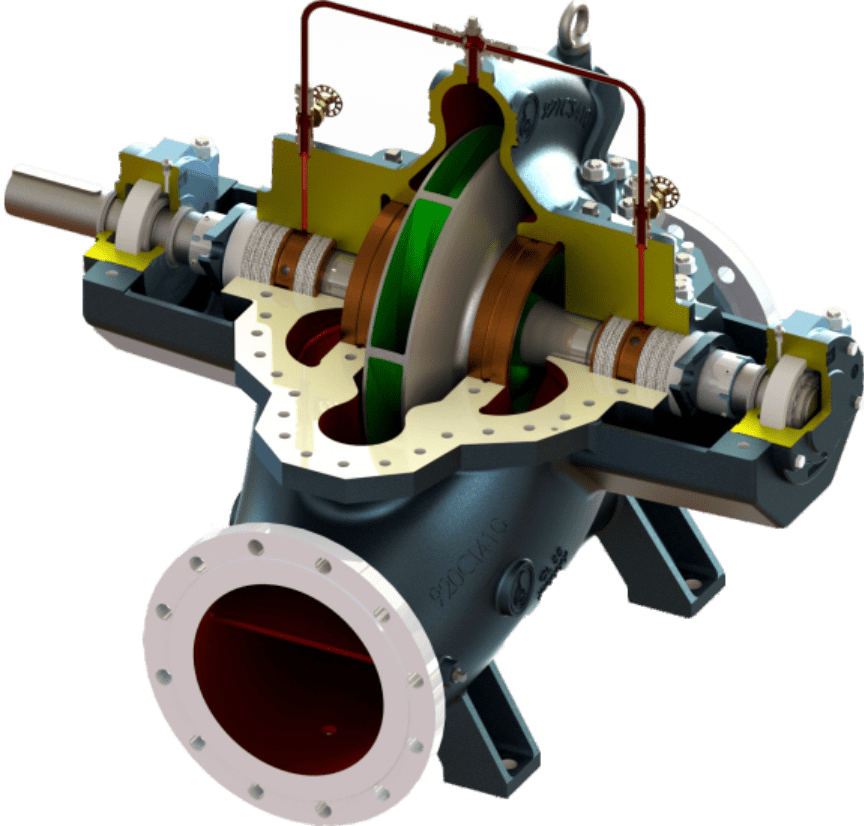

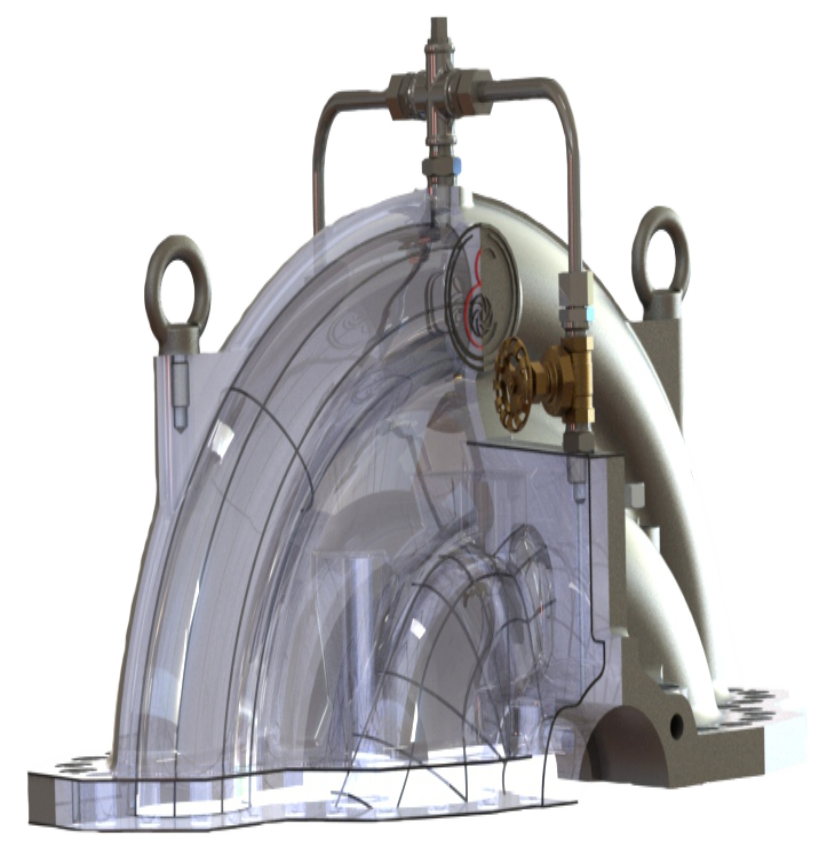

Closed double-suction impeller. The axial forces acting are hydraulically self-equilibrated.

Opposite, horizontal suction and discharge flanges positioned on the lower body. Due to its design characteristics, it can be driven in clockwise or counterclockwise directions.

ANSI standard-executed flanges.

Driven by electric motor, internal combustion, or steam turbine. Flexible coupling with or without spacer.

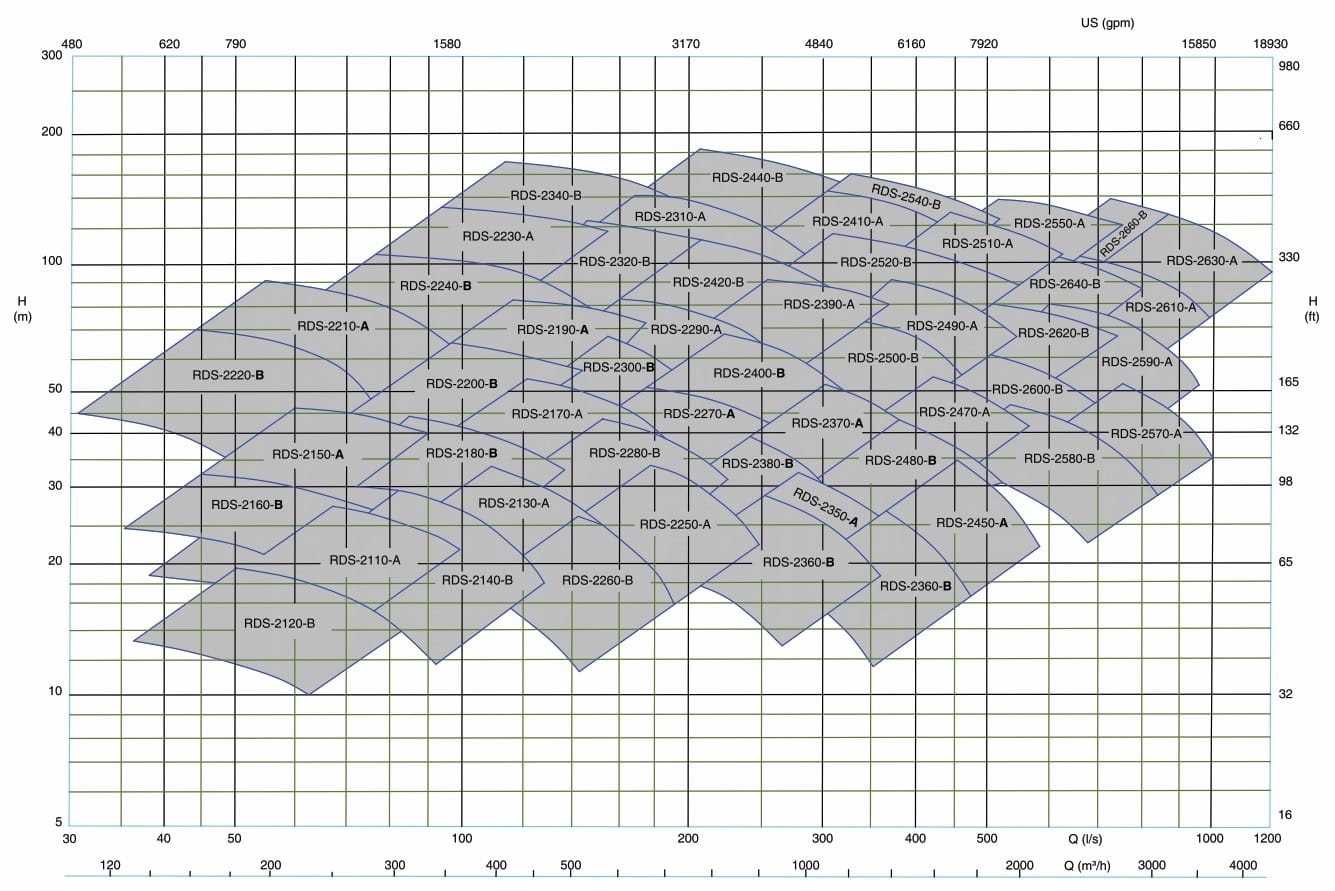

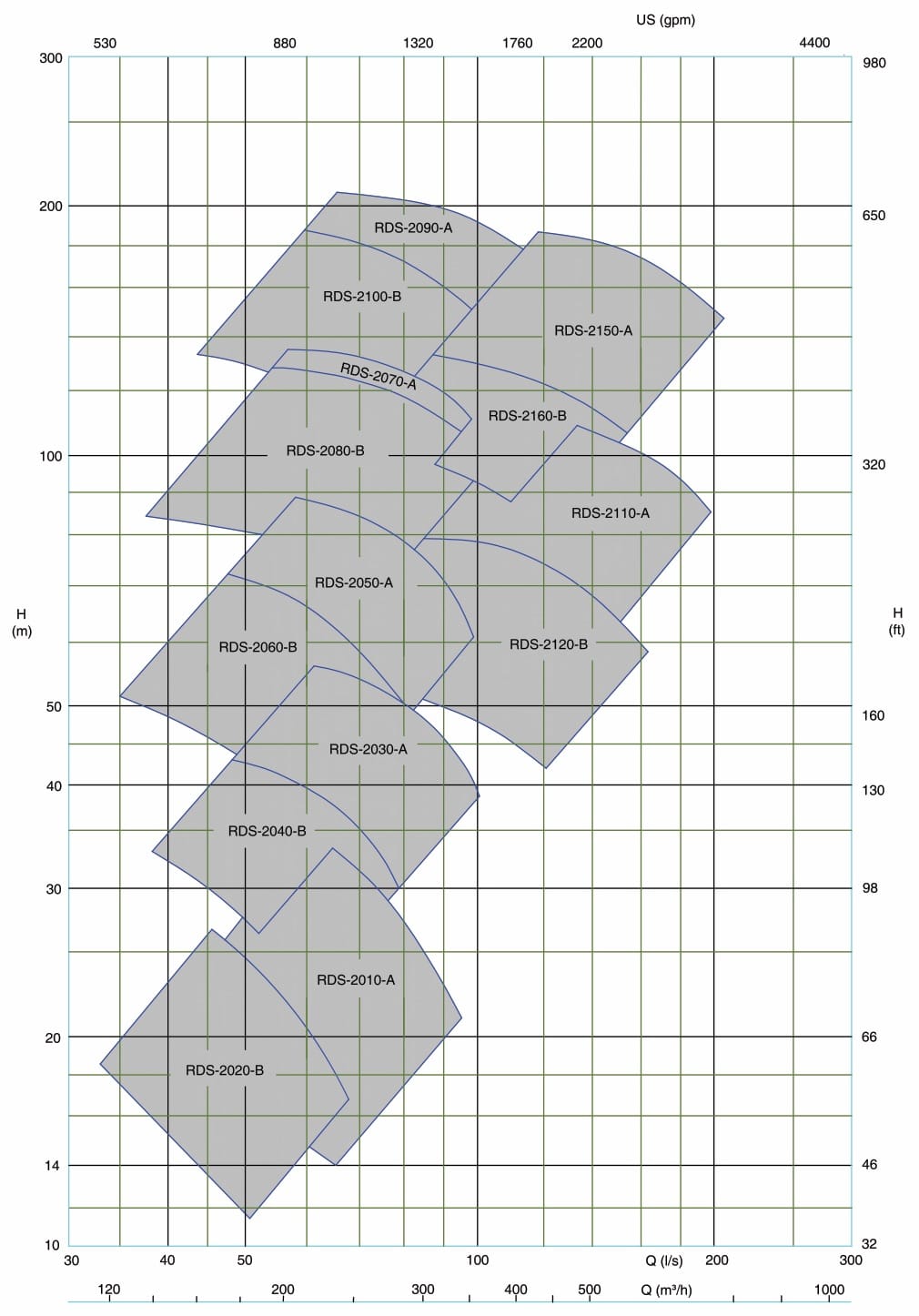

Head: up to 190m

Temperature: up to 110°C

Revolution: up to 3500 rpm

Flanges: padrão ANSI

Housing

Split in the direction of the shaft line, provided with removable wear rings.

They have support feet as an integral part of the lower body, cast in one piece.

The lower body houses the bearing housings with two-supported bearings at the ends. It allows easy access to the rotating assembly, without having to disconnect the suction and discharge piping.

Impeller

Built with staggered blades.

In specific applications, such as mixing pumps (Fumpumps), it can be designed with anti-pulsating vanes.

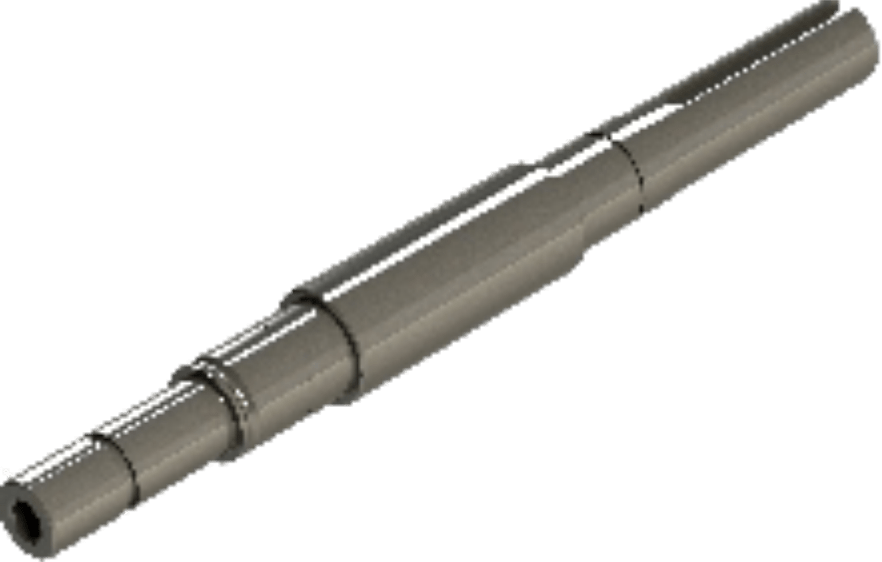

Shaft and Bearings

Oil bath lubricated compact bearings, sized according to ISO 281 (ANSI / ABMA standard 9).

Shaft for continuous services, designed for maximum load with minimum deflection.

Wide range of applications

Rugged construction

Proven durability, reliability, and efficiency Simplicity of maintenance

Support network and service flexibility

Technical support throughout the product life cycle Performance and cost-effectiveness that make the difference.

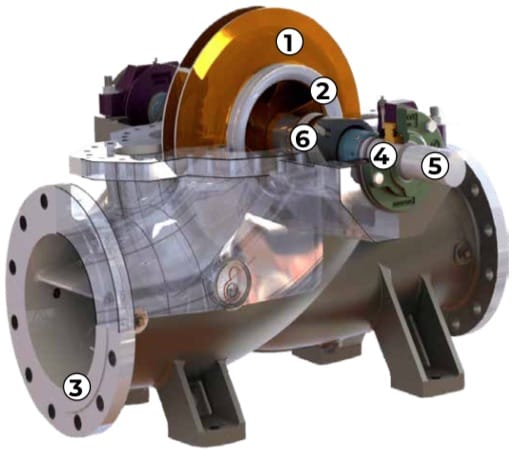

Closed, double-suction radial impeller, statically and dynamically balanced. Resulting axial forces self-balanced hydraulically, reduced axial thrust.

Low NPSHr. Vibration-free stable operation.

2) Labyrinth Rings

Replaceable, design tolerances and clearances guaranteed.

3) Connection Flanges

ANSI standard execution.

4) Bearings

Compact, robust rigid ball-type. Grease lubrication.

Allows easy installation.

Long-life warranty.

5) Shaft

Designed for heavy duty and minimum deflection, fitted with removable wear bushings.

Executed in carbon steel, or other alloys compatible with the liquid.

6) Sealing System

Conventional gaskets or mechanical seals.

The lubrication of the gaskets can be made by the pumped liquid itself or by an external source.