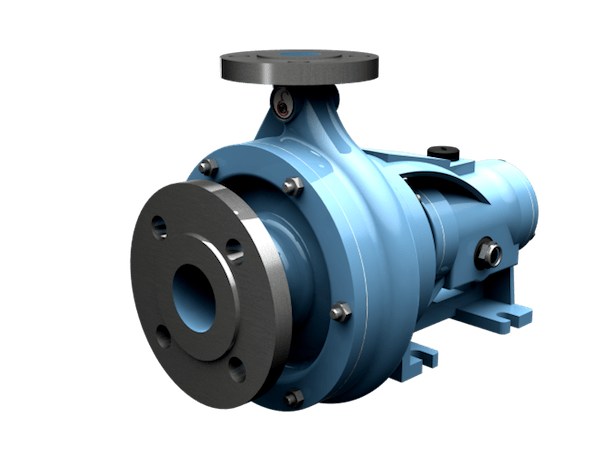

EQ Normalized Centrifugal Pump

The EQ-series centrifugal pumps are suited to pump liquids that are clean or slightly impure, with low impurity content, low viscosity, hot and corrosive.

They allow a broad usage in the most varied applications in the general industry.

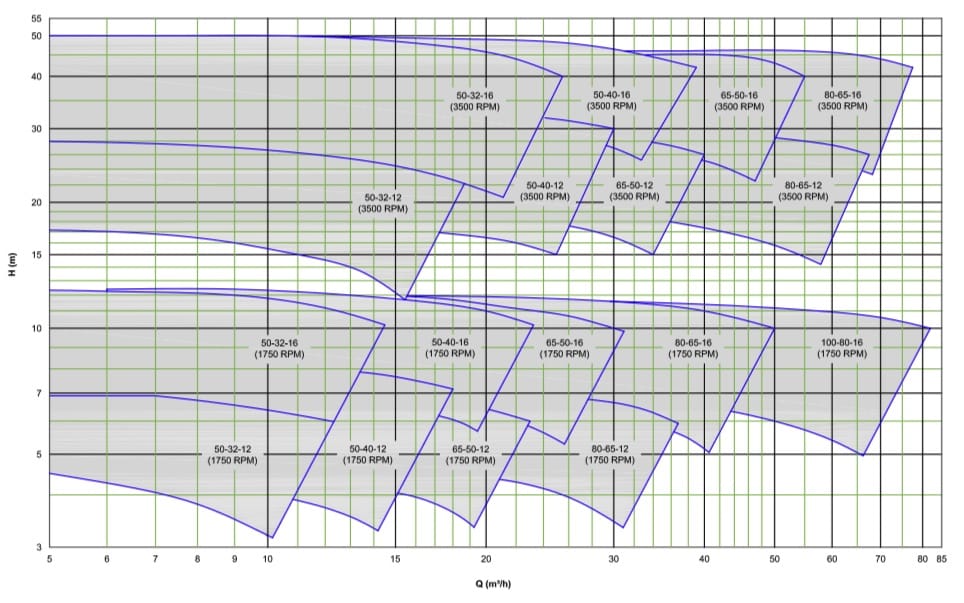

Hydraulic Characteristics

Impellers: Radial, one-stage, closed

Pressure: up to 5 Kgf/sq cm (g)

Flow: up to 100 m³/h

Temperature: up to 150°C

Revolutions: up to 3500 rpm

Contact

comercial@equipe-bombas.com.br

Areas of usage:

They are specially indicated for pumping liquids that are clean with low impurity content, low viscosities, hot, corrosive, acidic or alkaline.

- Textile industries,

- Food industries,

- Beverages industries,

- Sugar and alcohol mills,

- AC systems,

- Pumping of condensed and cooling systems,

- Civil construction,

- Building installations etc.

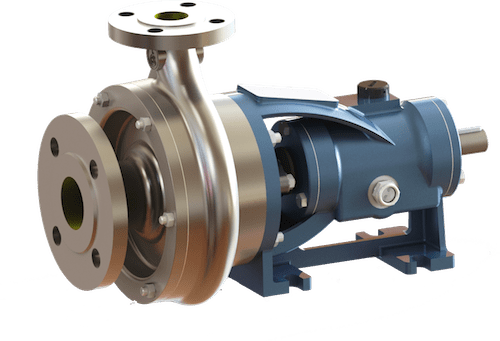

Volute

Spital-type volute, balance fixed to the bearing support. It has a vertical discharge flange, with the possibility of changing the position in 60° or 120° in relation to the center line in most models.

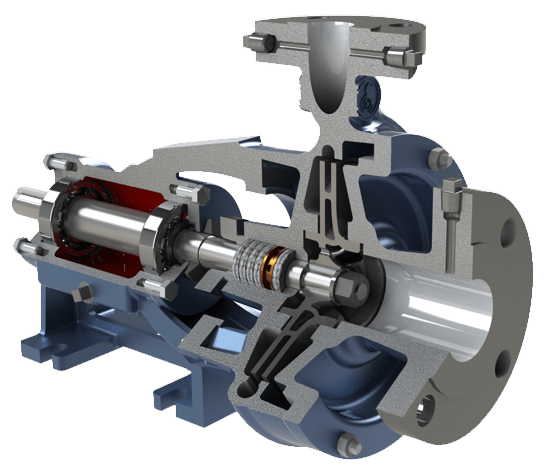

Impeller

The EQ-normalized series pump (closed impellers) may be used in the most varied industrial segments, show a high degree of components standardization allowing, thus, part interchangeability throughout the series.

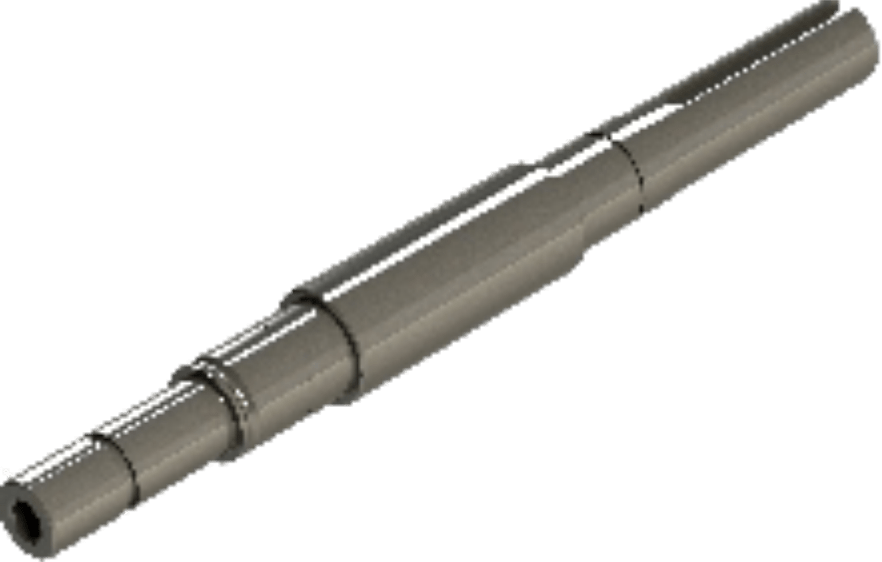

Shaft and Bearings

The axis works with oil-lubricated ball bearings, and the axis sealing is normally made with conventional gaskets.

Constructive Characteristics

Horizontal construction, single stage closed impeller, horizontal suction, and vertical discharge. Spiraled housing having replaceable wear rings.

Built with standardized components, allowing a high degree of part interchangeability, ensuring savings and simplification in the storage of spare parts.

Clockwise rotation, seen from drive. Activation by electric motor.

Oil-bath lubricated.

Execution in austenitic or martensitic stainless steels, gray or nodular cast iron, and special steels with or without specific heat treatments.

The suction and discharge flanges are built according to ANSI.

Built with conventional gasket or mechanical seal, compatible with the pumped liquid.

When gaskets are used, the axis is provided with replaceable wear sleeves, for higher protection and durability.

The mechanical seal may be double or single, internal or externally mounted.

Whenever necessary, or according to the service conditions, the stuffing box may be provided with cooling or lubrication by external/internal source systems.

1750 / 3500 RPM