Centrifugal Pump EQ

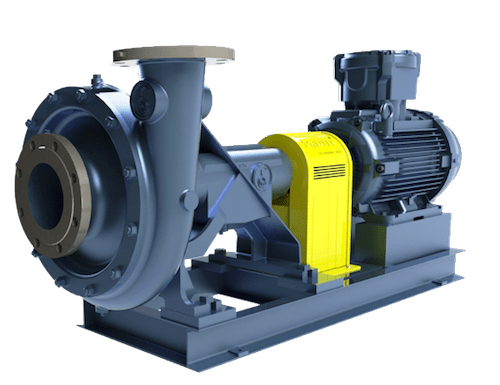

The EQ-series pumps (with closed impellers) have a broad field of application in the most diverse industrial segments.

They have components dimensioned to work in harsh conditions, allowing great sturdiness in the dimensioning of all their components.

Contact

comercial@equipe-bombas.com.br

Areas of usage:

- • Steel mills.

- • Paper and Cellulose industries.

- • Chemical industries.

- • Food industries.

- • Power supply.

- • City water supply and wastewater; treatment of raw sewage and/or wastewater in drainages in general.

- Pumping long fibers, muds, and sludge; fibrous pulp, fluid pastes and industrial effluents;

- Water/sand mixtures, slag and alike in mining industries;

- Wood chips with shavings;

- • Clean or slightly contaminated liquids, viscous liquids, etc.

Constructive Characteristics

The EQ-series centrifugal pumps are designed and built according to ANSI B-16.5 or B-16.1 150#.

Their execution is horizontal, single stage. The suction connection is axial horizontal, and the discharge is vertical.

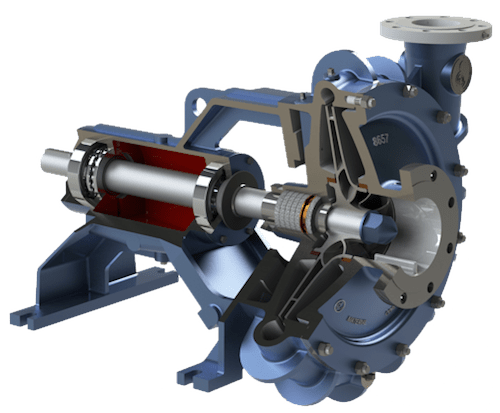

The shaft works with oil lubricated ball bearings and the shaft sealing is normally done by conventional gaskets and/or mechanical seals.

According to the work conditions, wear sleeves with special coatings, lubrication, cooling, or internal/external sealing can be provided.

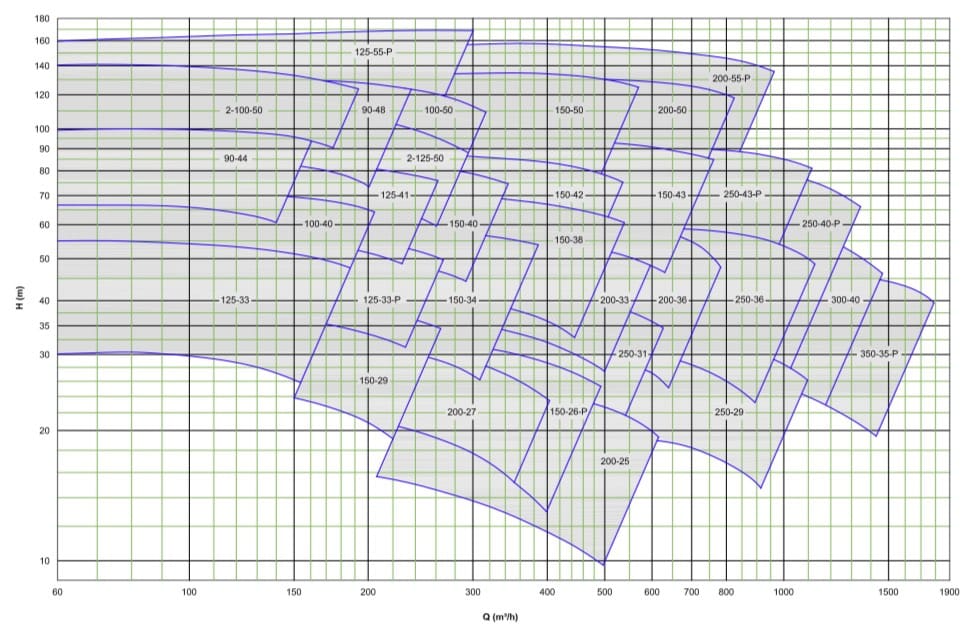

Hydraulic Characteristics

Impellers: Radial, closed

Pressure: up to 17.5 Kgf/sq cm (g)

Flow: up to 1800 m³/h

Temperature: up to 130°C

Revolutions: Up to 1750 rpm

Volute

Spital-type volute, balance fixed to the bearing support. It has a vertical discharge flange, with the possibility of changing the position in 60° or 120° in relation to the center line in most models.

Impeller

Closed impellers can be used in a broad application field in diverse industrial segments.

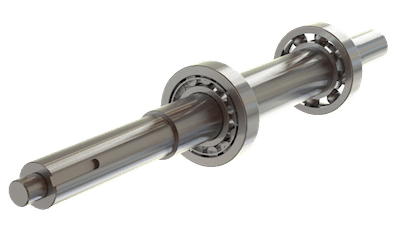

Shaft and Bearings

The shaft works with oil lubricated ball bearings and the shaft sealing is normally done by conventional gaskets and/or mechanical seals.

1750 RPM