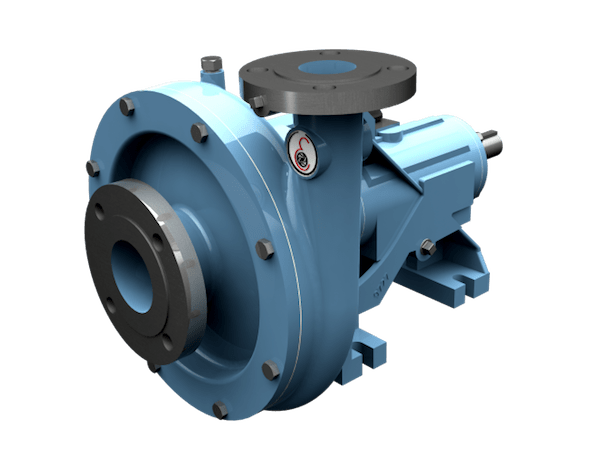

SN Centrifugal Pump

The SN series pumps are suitable for pumping clean or slightly impure, low impurity content, low viscosity, hot and corrosive liquids.

They allow broad coverage in the most varied applications in general industry.

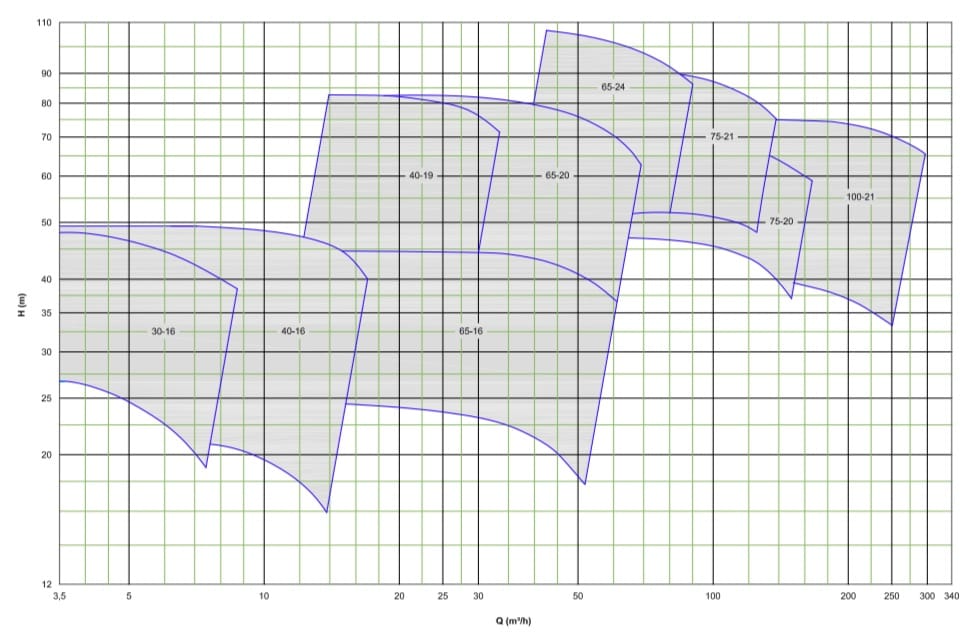

Hydraulic Characteristics

Impellers: Radial, closed

Pressure: up to 10 Kgf/sq cm (g)

Flow: up to 300 m³/h

Temperature: up to 150°C

Revolutions: up to 3500 rpm with limitations

Normalized construction, they are available in several sizes and may be used with temperatures up to 250°C

(~ 480°F) with cooling systems.

Contact

comercial@equipe-bombas.com.br

Areas of usage:

Different combinations of materials allow their use for the most varied applications, providing a broad hydraulic cover, efficiency, sturdiness and working stability.

They are specially indicated for pumping liquids that are clean with low impurity content, low viscosities, hot, corrosive, acidic or alkaline.

- • Steel mills.

- • Paper and Cellulose industries.

- • Chemical industries.

- • Food industries.

- • Power supply.

- • City water supply and wastewater; treatment of raw sewage and/or wastewater in drainages in general.

- Pumping long fibers, muds, and sludge; fibrous pulp, fluid pastes and industrial effluents;

- Water/sand mixtures, slag and alike in mining industries;

- Wood chips with shavings;

- • Clean or slightly contaminated liquids, viscous liquids, etc.

Constructive Characteristics

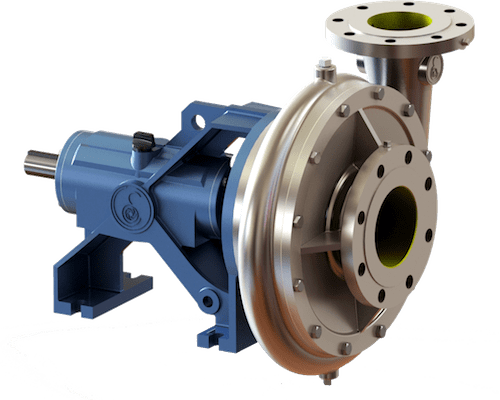

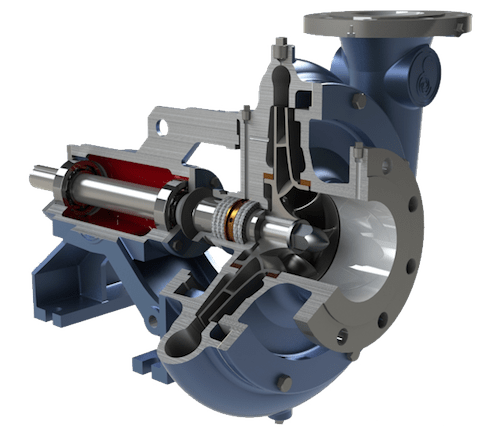

Horizontal, single-stage construction, closed impeller, horizontal suction, and vertical upwards discharge.

Built with standardized components, allows a high degree of interchangeability of parts throughout the series.

Clockwise rotation, seen from drive.

Standard drive with electric motors.

Oil bath lubrication.

Execution in austenitic or martensitic stainless steels, gray or nodular cast iron, and special steels with or without specific heat treatments.

Flanges

The suction and discharge flanges are built according to ANSI.

Sealing

The sealing may be made through conventional gasket or mechanical seal, compatible with the liquid characteristic.

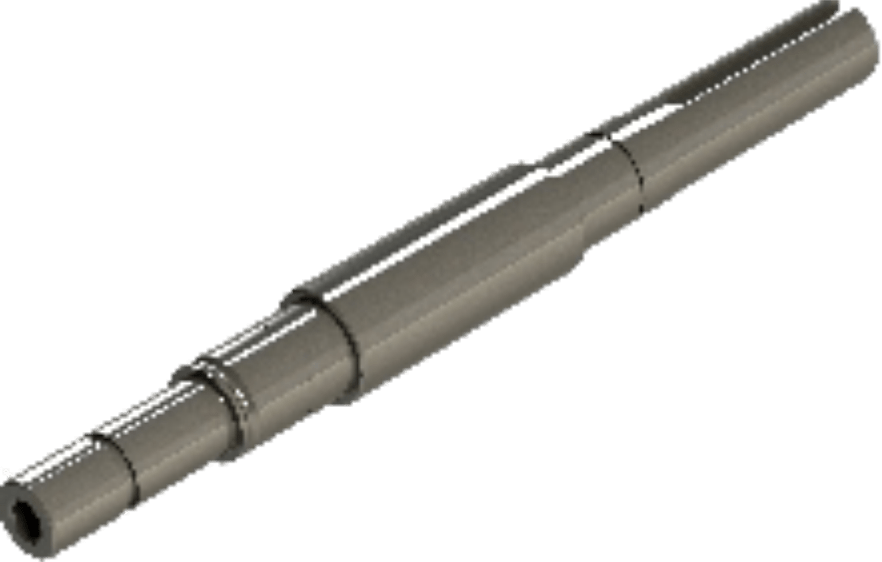

When gaskets are used, the shaft is provided with a replaceable wear sleeve, for higher protection and long life.

The mechanical seal may be simple or double, with internal or external assembly.

Whenever necessary or according to working conditions, the stuffing boxes may be provided with cooling or external/internal lubrication.

Coupling

Made through flexible coupling with or without spacer.

Casing

Casing and rotors cast in several materials, which allows a broad usage field.

Impeller

Closed, balance mounted. Statically and dynamically balanced to the axis.

Low NPSHr with high hydraulic frequency.

Shaft and Bearings

The axis works with oil-lubricated ball bearings, and the axis sealing is normally made with conventional gaskets.

3500 RPM