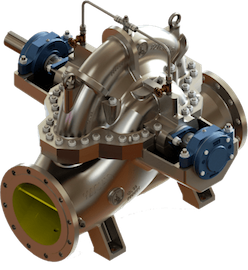

Split-casing Pump

Single-cell, double-suction, horizontal construction with axially split casing, double-suction closed radial impeller. The resulting axial forces on the impeller are hydraulically self-balanced and the body allows disassembly without having to remove the pipelines. In specific applications like mixture pumps, the impeller is projected with anti-pulsing pads.

The lower body stores the bearing housing with bearings dually supported in the edges. The suction and discharge flanges are horizontal, opposed and in the same level. The stuffing boxes have cooling chambers with water from an external source. The bearings are grease-lubricated and due to the project characteristics, they may be driven clockwise or counter-clockwise, seen from the coupling.

Electrical motor-driven, vapor turbine, with or without speed reducer.

Contact

comercial@equipe-bombas.com.br

Areas of usage:

- • Water Supply Centrals in Collection Systems

- Sewage Disposal

- Petrochemical companies

- • Cellulose and Paper

- • Cooling Stations

- Drainage

- • Firefighting

- • Power Plants

- • Oil Pipelines

Models

EQB Split Casing

Pressure: up to 10.5 Kgf/sq cm (g)

Flow: up to 6000 m³/h

Temperature: up to 120°C

Revolutions: up to 1750 rpm with limitations

RDS Split Casing

Pressure: up to 19 Kgf/sq cm (g)

Flow: up to 12000 m³/h

Temperature: up to 110°C

Revolutions: up to 3500 rpm