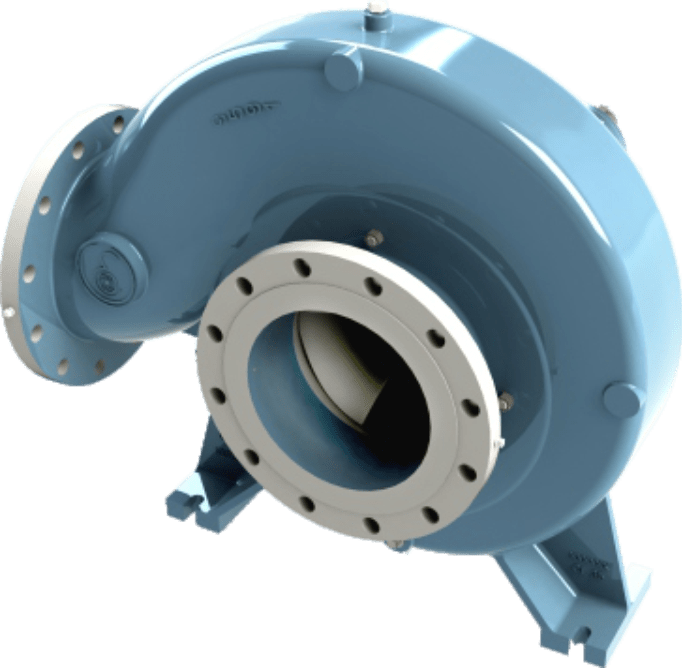

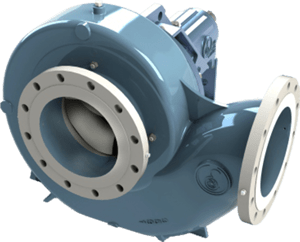

BCM-series Centrifugal Pump

Decades of experience in manufacturing hydraulic equipment for the transportation of liquids in general and a broad knowledge of systems and processes qualify Equipe Bombas as one of the main manufacturers in its segment.

We provide perfect engineering solutions, with maximum efficiency, reliability and significant advantages in modularity, interchangeability, and easy maintenance.

Project developed with specific materials for each purpose, in various conditions and environments. Economy, efficiency, and minimum wear of components with clog-free flow, especially for transporting fibrous liquids with high concentrations of solid impurities.

All components are manufactured to the highest quality standards in compliance with the ABNT ISO 9001 Quality Management System.

Contact

comercial@equipe-bombas.com.br

Areas of usage:

- • Steel mills.

- • Paper and Cellulose industries.

- • Chemical industries.

- • Food industries.

- • Power supply.

- • City water supply and wastewater; treatment of raw sewage and/or wastewater in drainages in general.

- Pumping long fibers, muds, and sludge; fibrous pulp, fluid pastes and industrial effluents;

- Water/sand mixtures, slag and alike in mining industries;

- Wood chips with shavings;

- • Clean or slightly contaminated liquids, viscous liquids, etc.

Constructive Variations

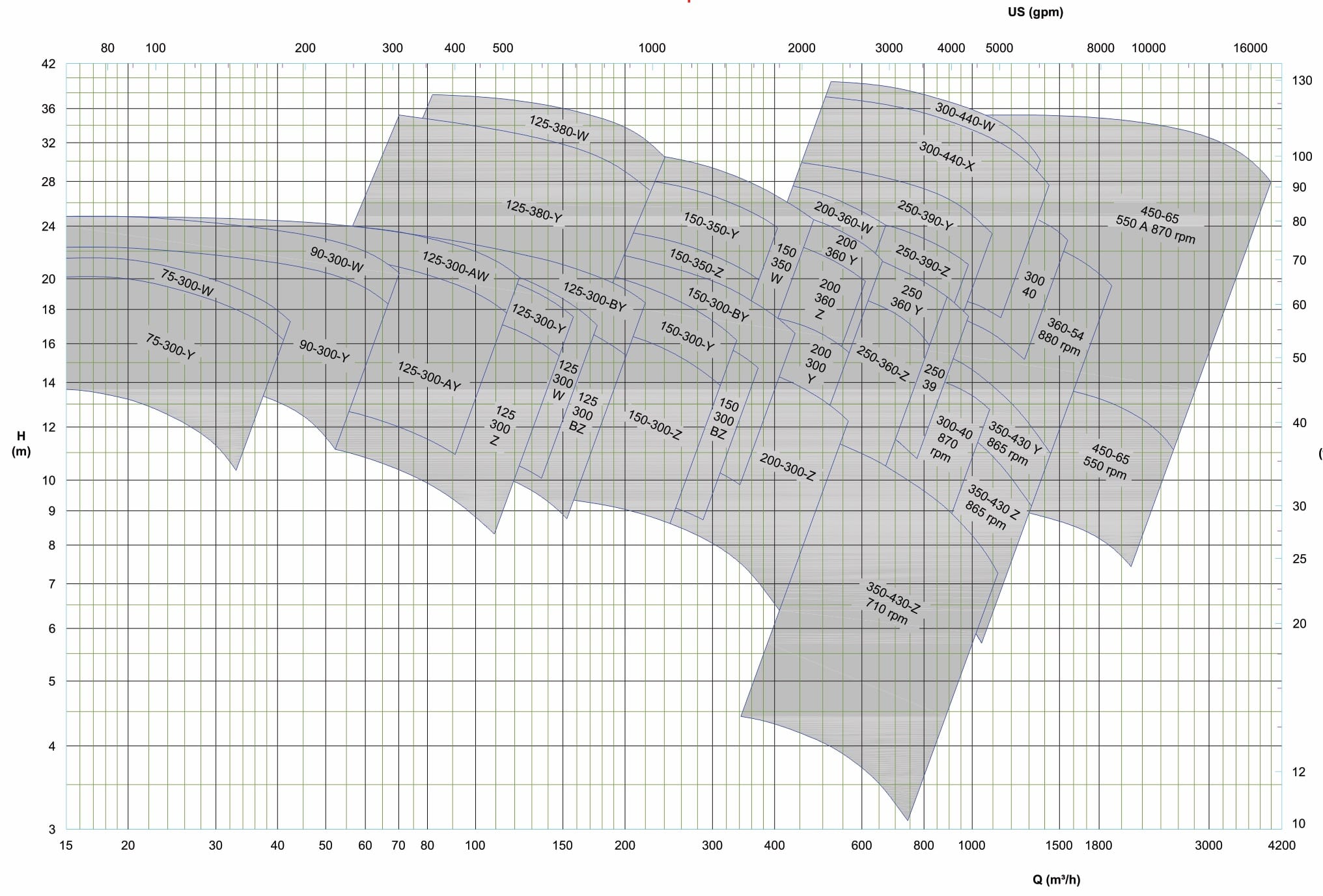

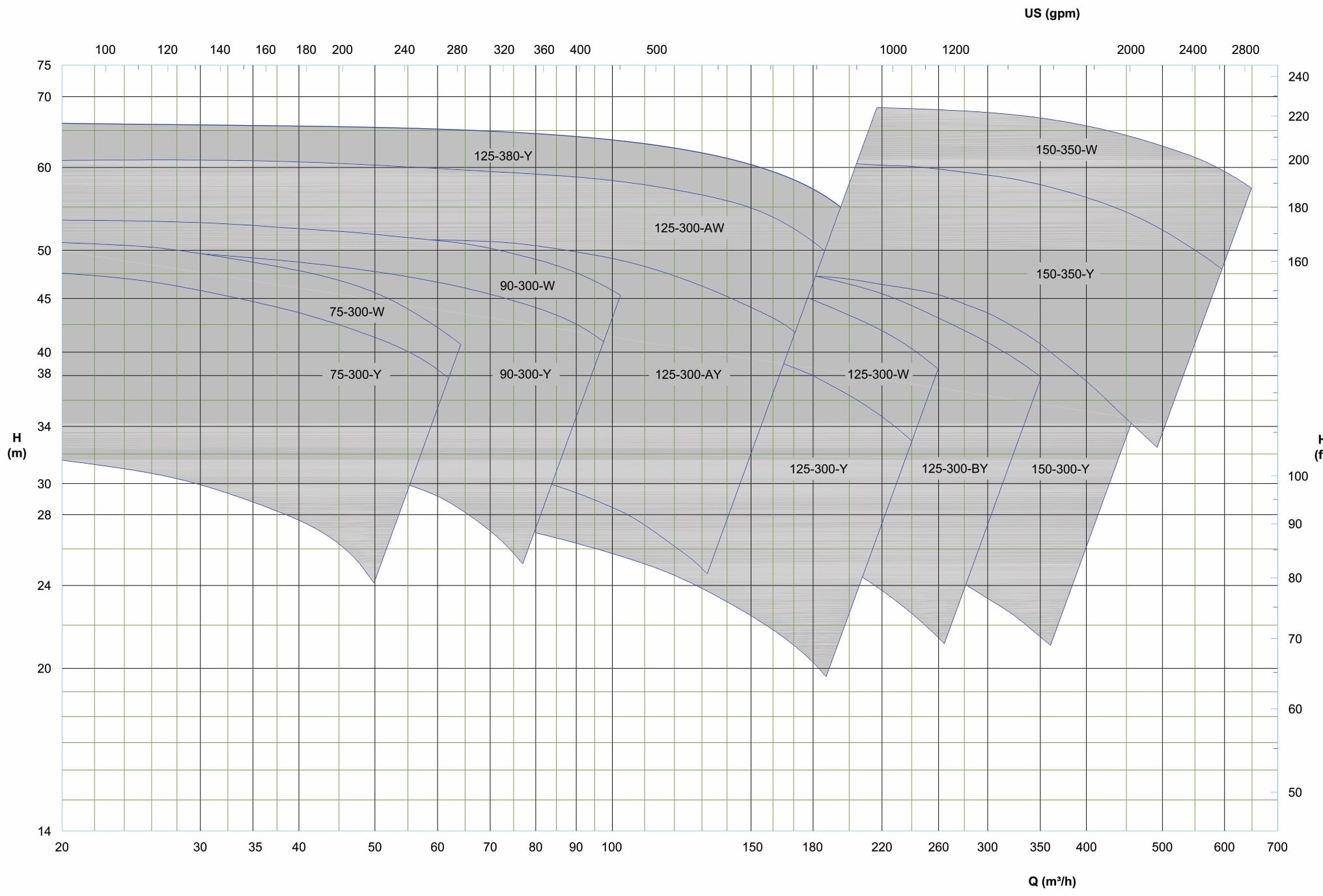

BCM HE

Impellers: Open, 2 to 5 vanes

Flows: up to 4000 cu m/h

Head: up to 65 m

Temperature: up to 120°C

Revolutions: up to 1780 rpm

Frequency: 50 or 60 Hz

Pressure: up to 6.5 Kgf/sq cm (g)

BCM

Impellers: Open, 2 to 5 vanes

Flows: up to 4000 cu m/h

Head: up to 65 m

Temperature: up to 120°C

Revolutions: up to 1780 rpm

Frequency: 50 or 60 Hz

Pressure: up to 6.5 Kgf/sq cm (g)

BCM HD

Impellers: Open, 2 to 5 vanes

Flows: up to 4000 cu m/h

Head: up to 65 m

Temperature: up to 120°C

Revolutions: up to 1780 rpm

Frequency: 50 or 60 Hz

Pressure: up to 6.5 Kgf/sq cm (g)

Constructive Characteristics

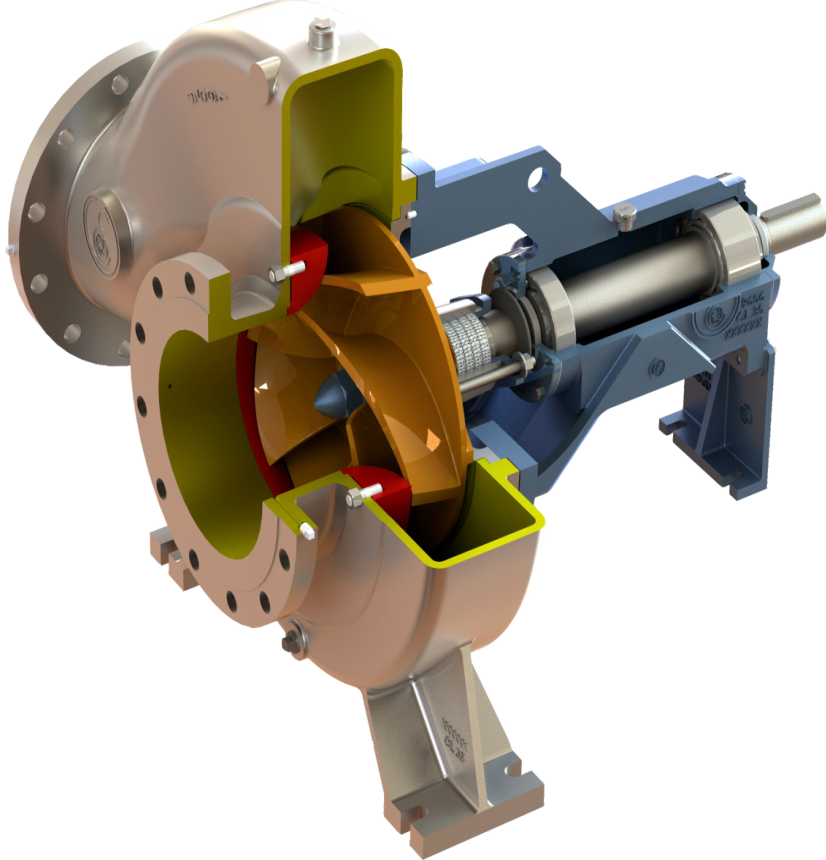

Robust construction, indicated for continuous and heavy-duty service, present excellent resistance to wear and tear and to the harshest operating conditions. The casing is provided with shoes for fastening to the base, holding the suction and discharge flanges in a single set. With open impeller, it has rear fins for axial thrust reduction. It presents characteristics of the hub construction, which is quite recessed in relation to the inlet, allowing a wide passage, reducing clogging. Horizontal construction, Back-Pull-Out design, presents easy disassembly. Axial suction and discharge flanges with assembly options: centralized on the vertical upwards position, horizontal to the right (HD) and/or to the left (HE), standardized according to ANSI or ASME Standards.

Oil bath lubrication.

Wide passage, blades designed with double curvature, enabling optimum performance in pumping liquids containing solid residues such as mud, sludge, or fibrous pastes. Usable in pumping with high concentrations of air, juices with long fibers, effluents, shavings, chips, etc.

Similar construction and similar applications, with the following additional features: enables higher flow rates and pressures; used for pumping other solid/liquid mixtures with more homogeneous characteristics.

Presents great hydraulic efficiency with low power consumption. Low NPSHr.

Provides higher resultant pressures when compared to previous impellers.

Applicable for the discharge of mixtures with comparatively lower concentrations of solids and percentages of fibrous materials.

Provides higher pressure gain when compared to its predecessors and higher hydraulic performance for the same flow rate. Ideal for homogeneous mixtures applications, containing short fibers of low and medium densities and medium viscosity liquids.

Construction

- Modular; with superior design features; reliability with maximum efficiency;

- Reduced operational costs;

- High level of standardization and spare parts cost.

Back Pull Out Design

Allows easy access to the rotating assembly and quick maintenance, reduces costs and unscheduled downtime.

Construction materials

Wide range and combinations of construction materials available, depending on the pumped liquid.

Allows the transportation of liquids with high concentrations of suspended solids up to 150mm.

Replaceable wear plates with profiles designed according to the impeller design.

Superior design characteristics; Double-bent impeller; Low required NPSH. Low energy consumption.

Conventional sealing designed according to ISO dimensional standards with gaskets or single/double mechanical seals, sealing plans according to API-610 – 6th edition.

Shaft designed for minimum deflections ≤ 0.05mm. Specific materials for each application. Sturdiness, Durability and Operational Safety.

Compact and robust bearings, dimensioned for high load capacity, long life. Oil lubrication for temperatures up to 120°C.

Designed casing, large cross section raceway, clog-free flow.

Provided with replaceable wear sleeve for protection of the shaft against corrosion and wear.