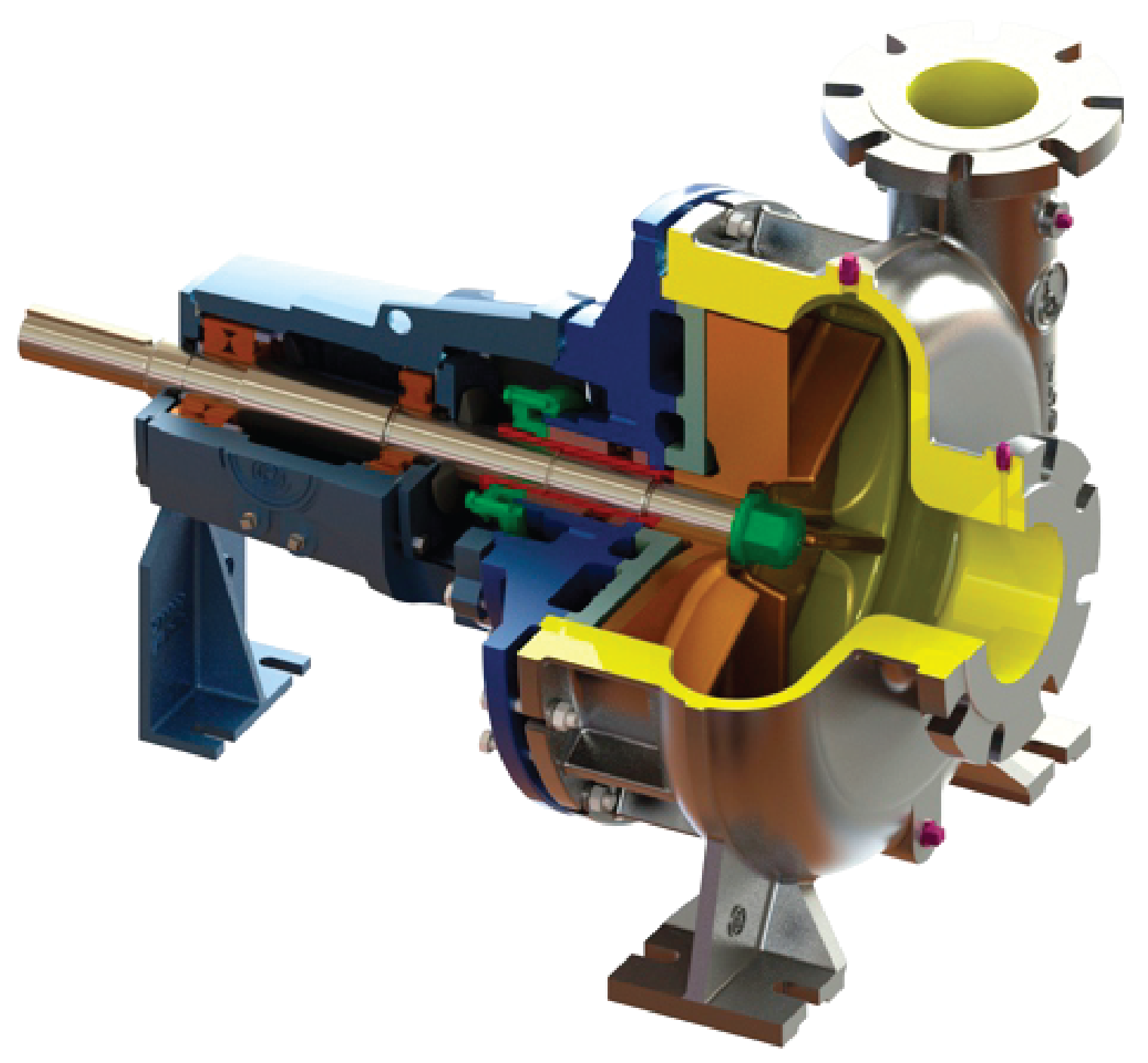

VTX and SVTX-series Centrifugal Pump

Simple construction, easy to handle, with no need for specialized labor. It has diversified applications covering most sectors of industries in general.

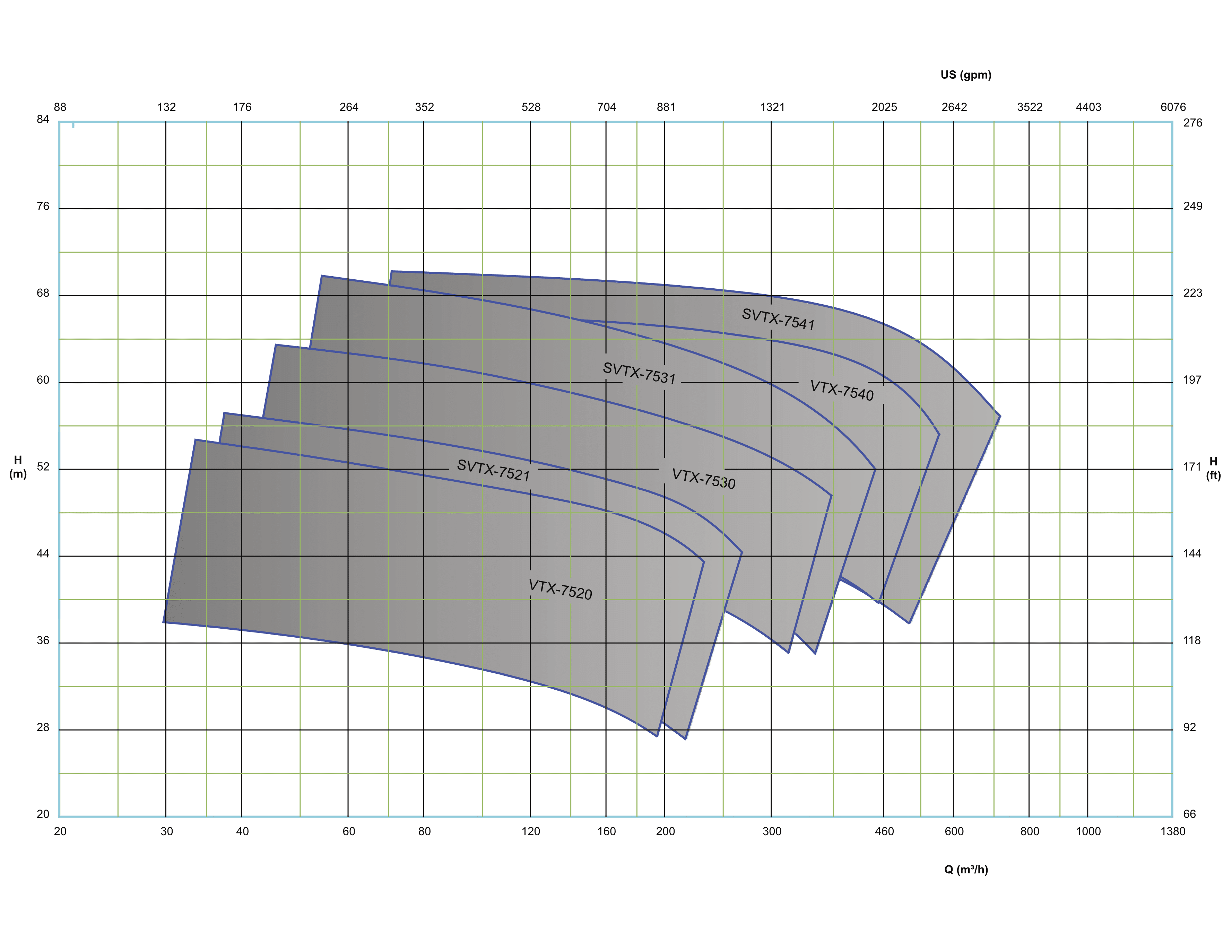

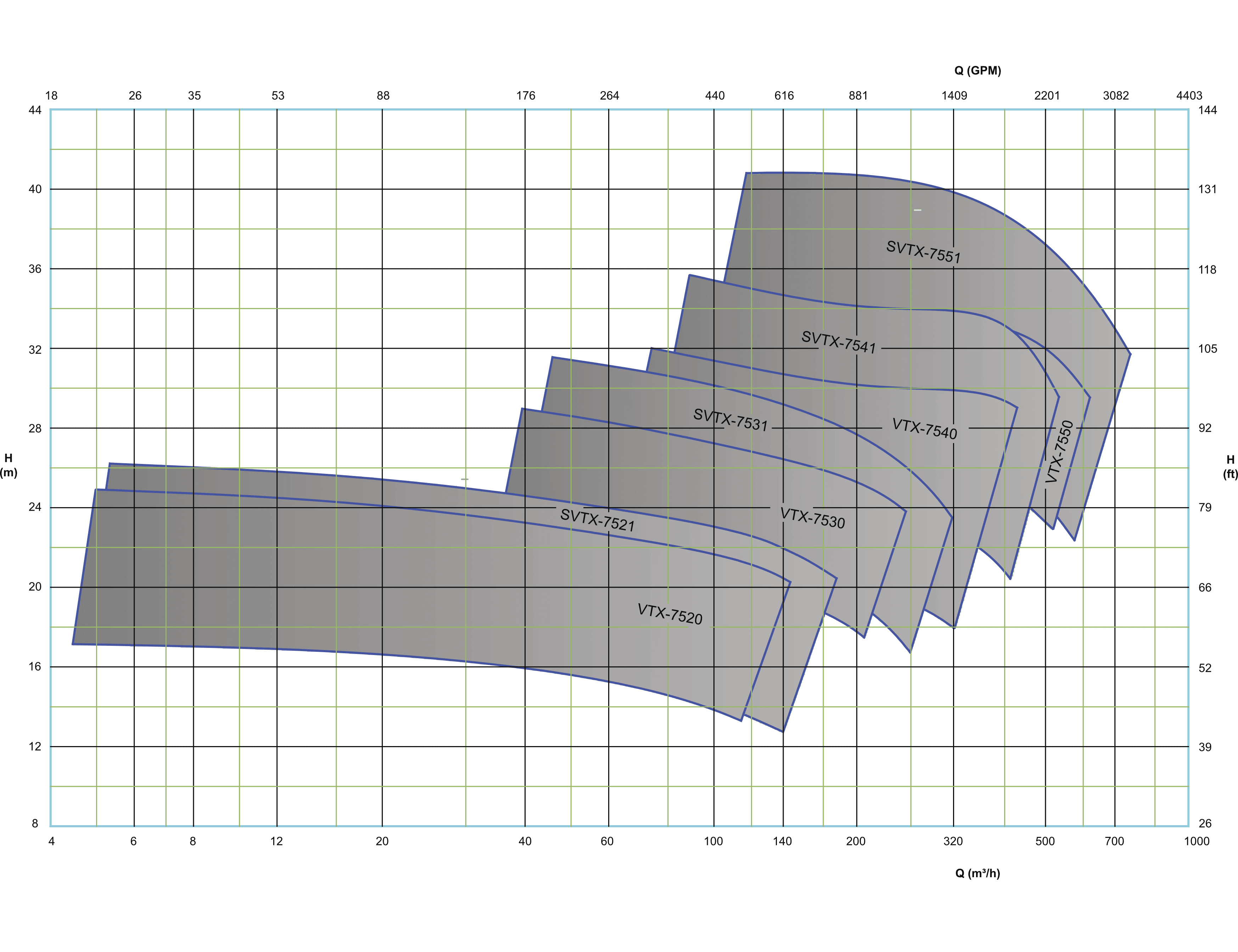

The VTX / SVTX series offer broad hydraulic coverage, efficiency, sturdiness, and stability of operation. Composed of modular elements for the various sizes, which considerably reduces the maintenance of spare parts inventory.

Mechanically built according to the ANSI / ASME B-73.1 standard.

Durability and minimum wear make this design one of its main features, in the application of pumping liquids with high content of solid residues.

Contact

comercial@equipe-bombas.com.br

Areas of usage:

- Sugar and Alcohol: Sooty water from gas washing, cane washing

- Paper and cellulose: Cellulose pulp

- Textile Industry

- Sanitation: Water from effluent treatment plants, raw sewage

- Mining: Ore slurry in general

- Food Industry: Sensitive liquids discharge Process residues

- Sand extraction

- Civil construction

- Steel Industries: Residues from casting furnaces.

Constructive Variations

Constructive Characteristics

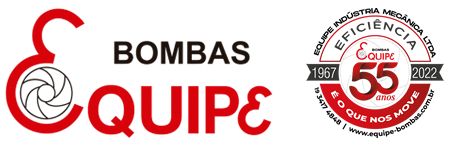

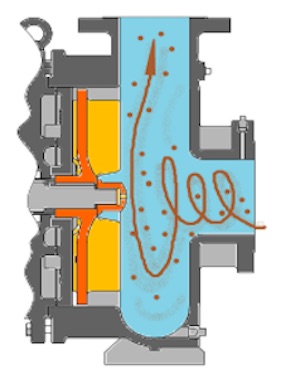

- Horizontal execution, radially split casing with broad passage for solids and particulates. It bears horizontal suction and vertical discharge, recessed open impeller, Vortex or Semi-Vortex type.

- Standard flanges according to ANSI B-16.5 – 150#.

- Construction form ANSI / ASME B-73.1 (Back Pull-Out System). Allows disassembly for eventual repairs from the back side, without the need of removing pipes and/or electric motor.

- Mechanical design with interchangeable and standardized modular elements.

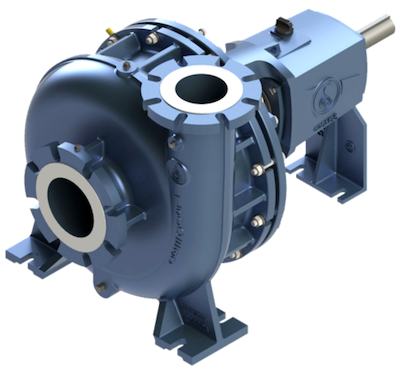

Casing

One-piece cast supported by two feet on sturdy frame. Construction materials compatible with the pumped liquid. Back pull-out construction. It has a drain plug, primer, and pressure test ports for gauge installation on suction and discharge. The fixing holes in the feet, rear cover and flanges are opened laterally, which contributes to an agile and easy maintenance.

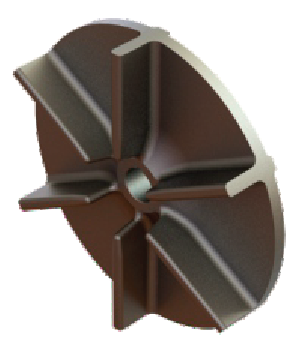

Impeller

High efficiency with broad hydraulic coverage.

Semi-open type recessed (Vortex) or semi-recessed (Semi-Vortex). Statically and dynamically balanced. It boasts rear vanes for axial thrust relief and sealing box protection.

Shaft

Compact, oil bath lubricated bearings. Dimensioned according to ISO 281 (ANSI / ABMA standard)

High-Chromium White Cast Iron Ni-Hard

Optional high-hardness material for application in impeller and volute.

Provides increased component life.

It is indicated when the pumped liquid contains high content of abrasive solids in suspension.

Construction

Horizontal, radially split casing with broad passage of solids and large particles. It has horizontal suction and vertical discharge, open recessed vortex, or semi-vortex-type impeller.

Constructive shape ANSI / ASME B-73.1. Standard flanges: ANSI B-16.5 – 150#.

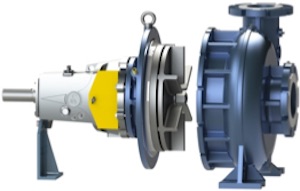

Back Pull Out Design

Mechanical design with interchangeable modular elements with standardization of parts and reduced number of spare components.

Easy maintenance: allows disassembly for eventual repairs from the back, without the need of removing the pipes and/or electric motor.

Metallurgy

Wide variety of construction materials, compatible with the product, allows use in the most varied applications.

Protection of the rotating parts

Polyethylene protector in accordance with NR-12 standard requirements.

Flexible couplings with spacers, providing quick and safe maintenance.

Screwable gasket tightener

Greater reliability and safety for the sealing box.

Bearing support

Guaranteed stability and rigidity of attachment. Provides great robustness, with thick walls and a high degree of concentricity. It can be removed without removing the pipes and allows for easy and quick alignment. Bearing housings lubricated by oil bath.

Bearings

Robustness and stability in axial thrust compensation, allowing optimum distribution of radial loads.

Rear Wear Plate

Built in high hardness materials. Protection and wear resistance.

Horizontal spiral body

Cast in special high hardness materials, with excellent durability in pumping abrasive liquids.

Shaft

Dimensioned for heavy and continuous services, minimum deflection guarantee.

Semi-open recessed or semi-recessed impeller

Suction with broad solids passage. High resistance to abrasion wear. Low NPSHr and high hydraulic efficiency.

Allows the discharge of liquids containing high concentrations of large solids.

1150 RPM

1750 RPM