BPO-series Pumps

The BPO series were mechanically projected according do ANSI B73.1, presenting advantages as withdrawal of the support assembly and hydraulic element with no need to detach the piping and driver element. They offer broad hydraulic coverage, roughness, working stability and efficiency with low energy consumption.

Used in the transportation of clean or slightly turbid liquids in drainage, irrigation, water supply in communities, power stations in cooling systems, industrial effluents, collection, etc. Different combination of materials allow their use for the most diverse demands.

Contact

comercial@equipe-bombas.com.br

Areas of usage:

- • Steel mills.

- • Firefighting.

- Irrigation;

- • Paper and Cellulose industries.

- • Chemical industries.

- • Food industries.

- • Power supply.

- • City water supply and wastewater; treatment of raw sewage and/or wastewater in drainages in general.

- • Sugar and alcohol.

- • Civil construction.

- • Textile industries.

- • Clean or slightly contaminated liquids, viscous liquids, etc.

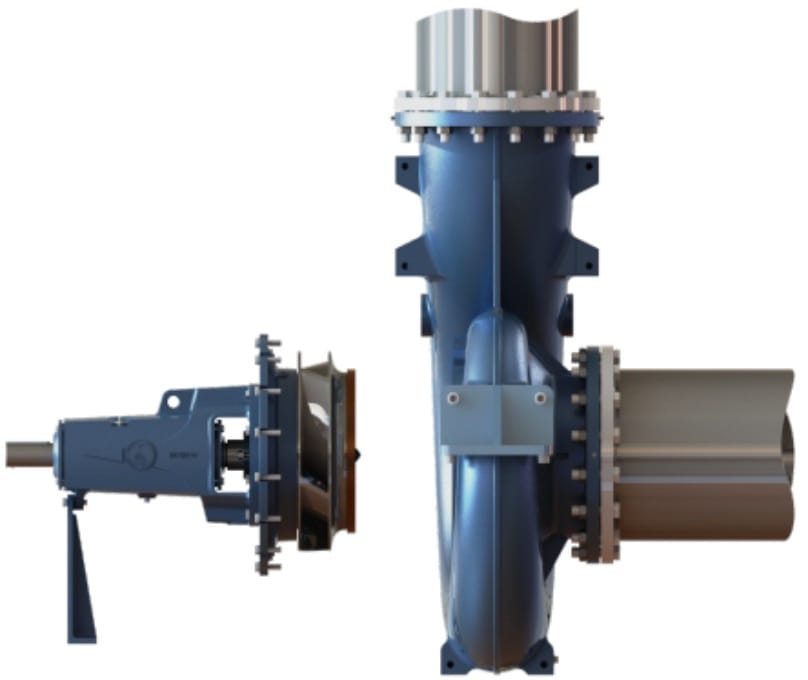

Assembly Variations

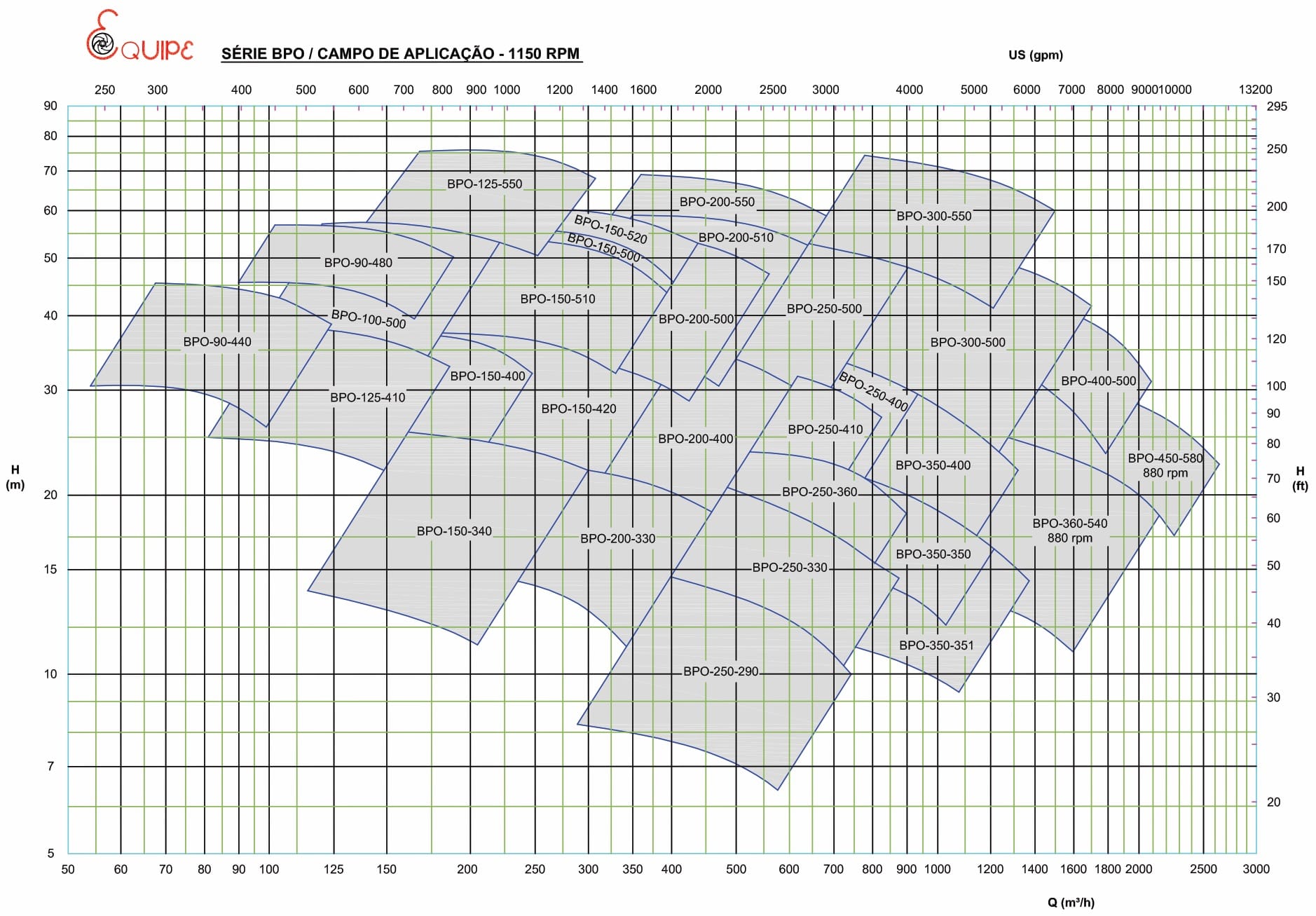

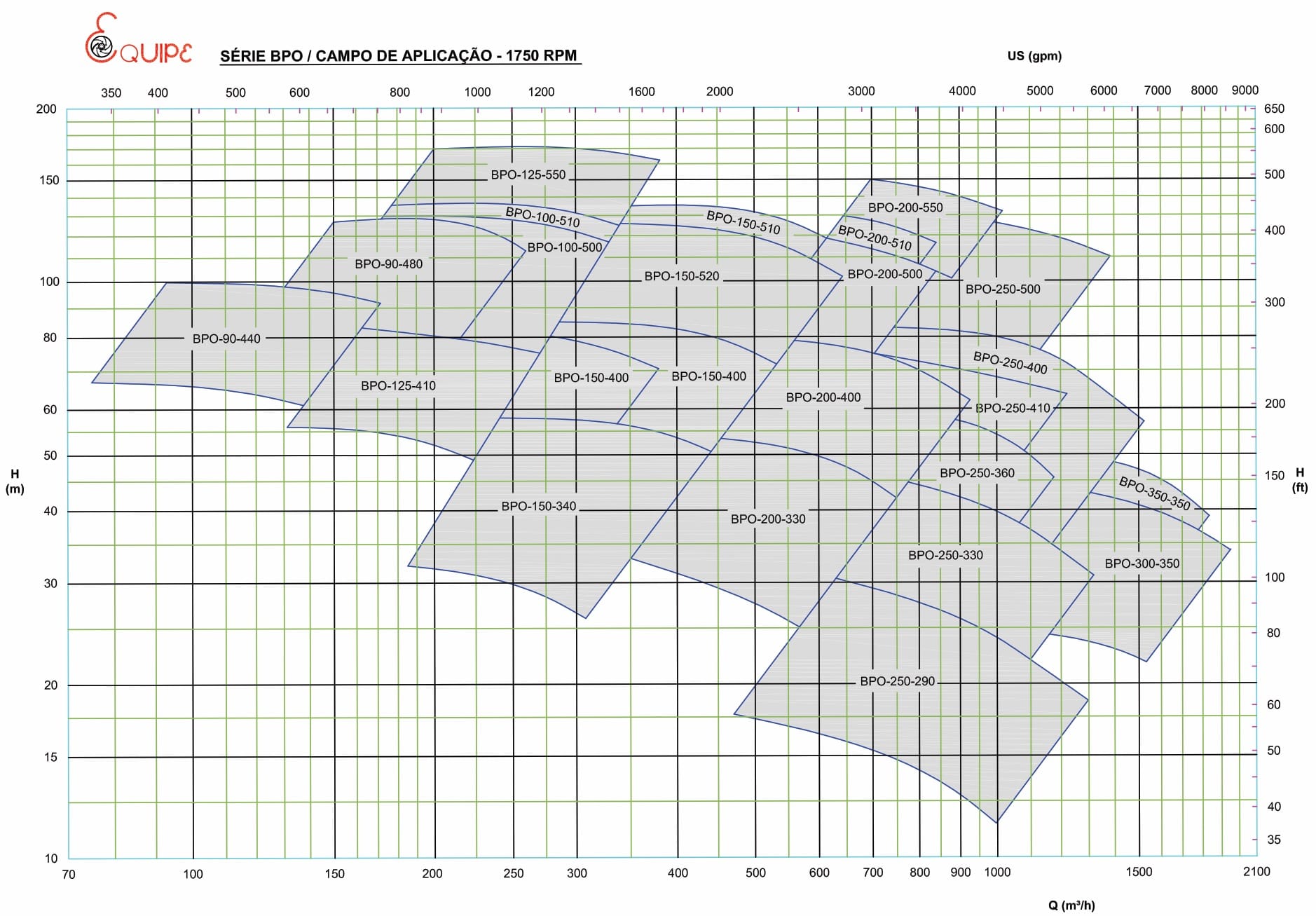

BPO

Impellers: Closed

Pressure: up to 150 m

Flow: up to 2500 m³/h

Temperature: up to 110°C

Revolutions: up to 1750 rpm

BPO HD

Impellers: Closed

Pressure: up to 150 m

Flow: up to 2500 m³/h

Temperature: up to 110°C

Revolutions: up to 1750 rpm

BPO HE

Impellers: Closed

Pressure: up to 150 m

Flow: up to 2500 m³/h

Temperature: up to 110°C

Revolutions: up to 1750 rpm

Constructive Characteristics

Horizontal execution, single cell radially bipartite, with closed impeller, horizontal simple suction, and discharge with assembly options vertical centralized, horizontal to the right (HD) or horizontal to the left (HE). Standardized construction, using modular elements for the several sizes. Fewer replacement parts.

BPO (Back-Pull-Out)

Easiness for replacing components and optimization of downtime, with fast OEM replacement. Low operational cost.

Casing

Spiral type, cast in a single part with support feet for the trestle support. Construction materials compatible with the liquid being pumped.

Back Pull-out construction provided with replaceable wear rings.

Support feet located on the axis center line. Tensions from the piping are compensated with the lowest reaction possible.

Impeller

High efficiency with broad hydraulic coverage. Closed, radial, simple suction, provided with replaceable wear rings. Low NPSHr with continuous performance. Statically and dynamically balanced. The axial thrust is compensated through vanes and/or relief holes.

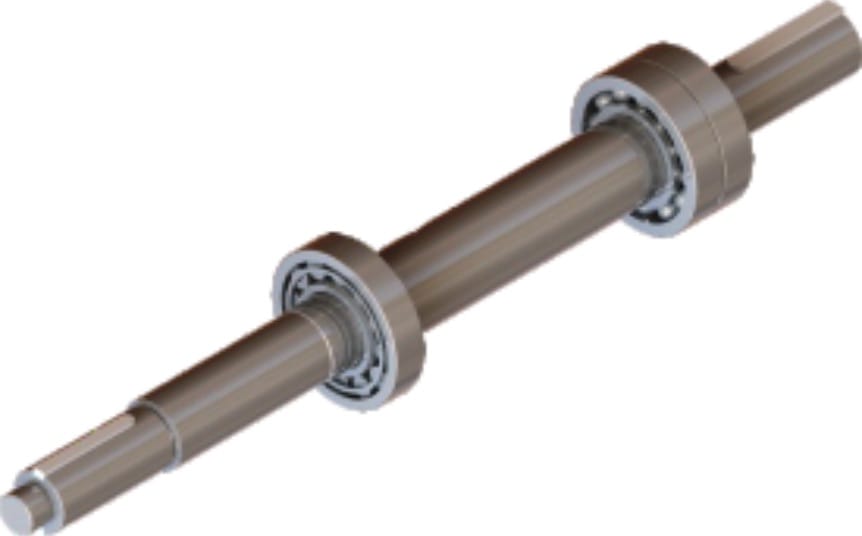

Shaft and Bearings

Compact ball bearings, oil-bath lubricated, with dimensions according to ISO 281 (ANSI/ABMA standard 9).

Axis for continuous services, projected for maximum load and minimum deflection.

High hydraulic yield, bringing energy savings. Coverage flexibility with broad range of applications. With direct drive, transmissions through belts/pulleys and/or frequency inverters.

Back pull-out design

Utilization of standardized elements with low maintenance cost and downtime. All the parts subject to wear are easily replaced. It is not necessary to remove piping and the drive motor.

Construction materials

Cast iron, carbon steel, bronze, or stainless steels.